[Sep 18 – Apologies for the belated posting. Here’s the update from Daniel. – Eric]

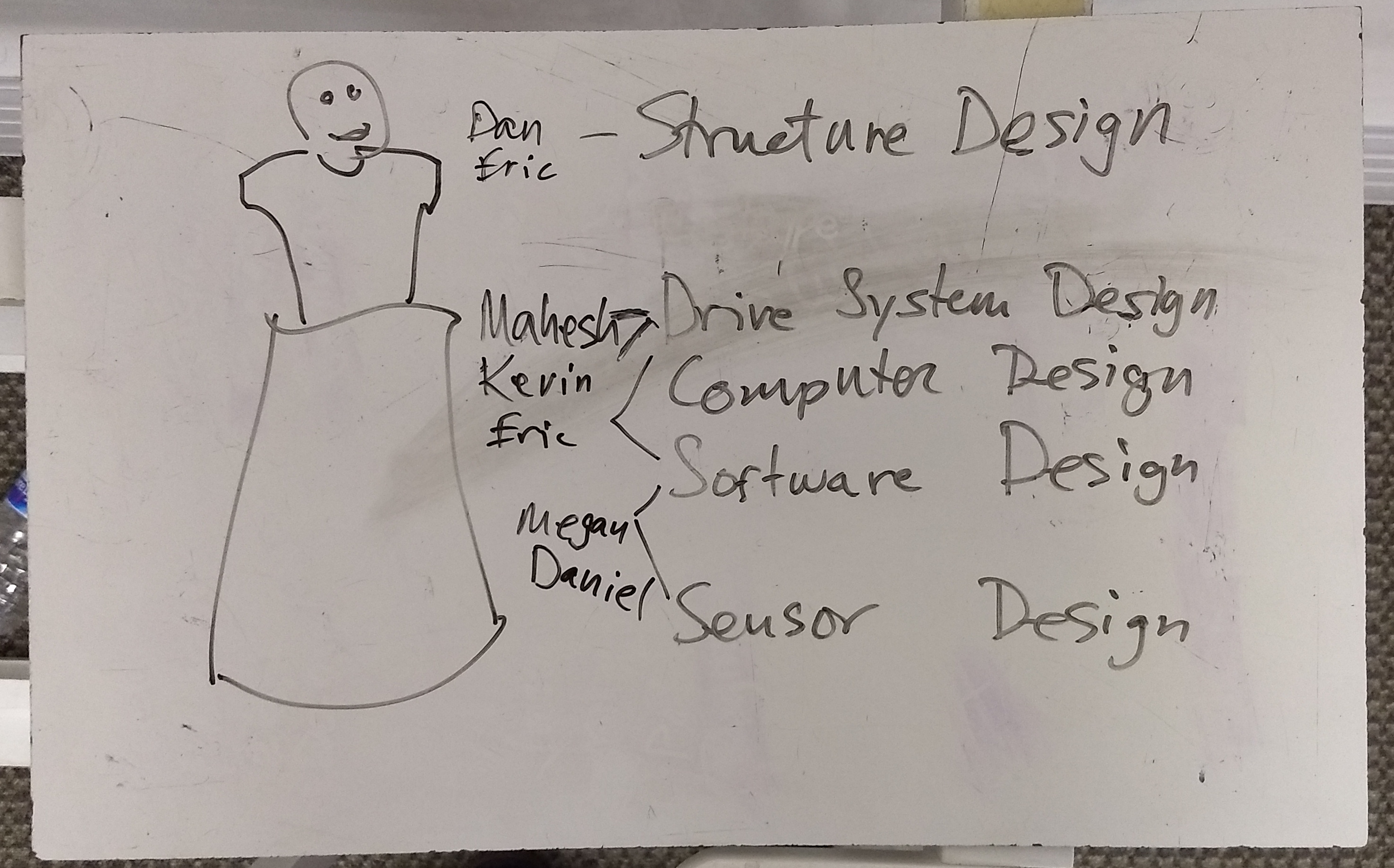

We continued discussions on the mobile navigation base drive system and reviewed past PyroTech robots for inspiration. The next step is to draw up some design ideas and work out the interfaces between the drive system and the superstructure to ensure we have the right dimensions for everything to fit in place.

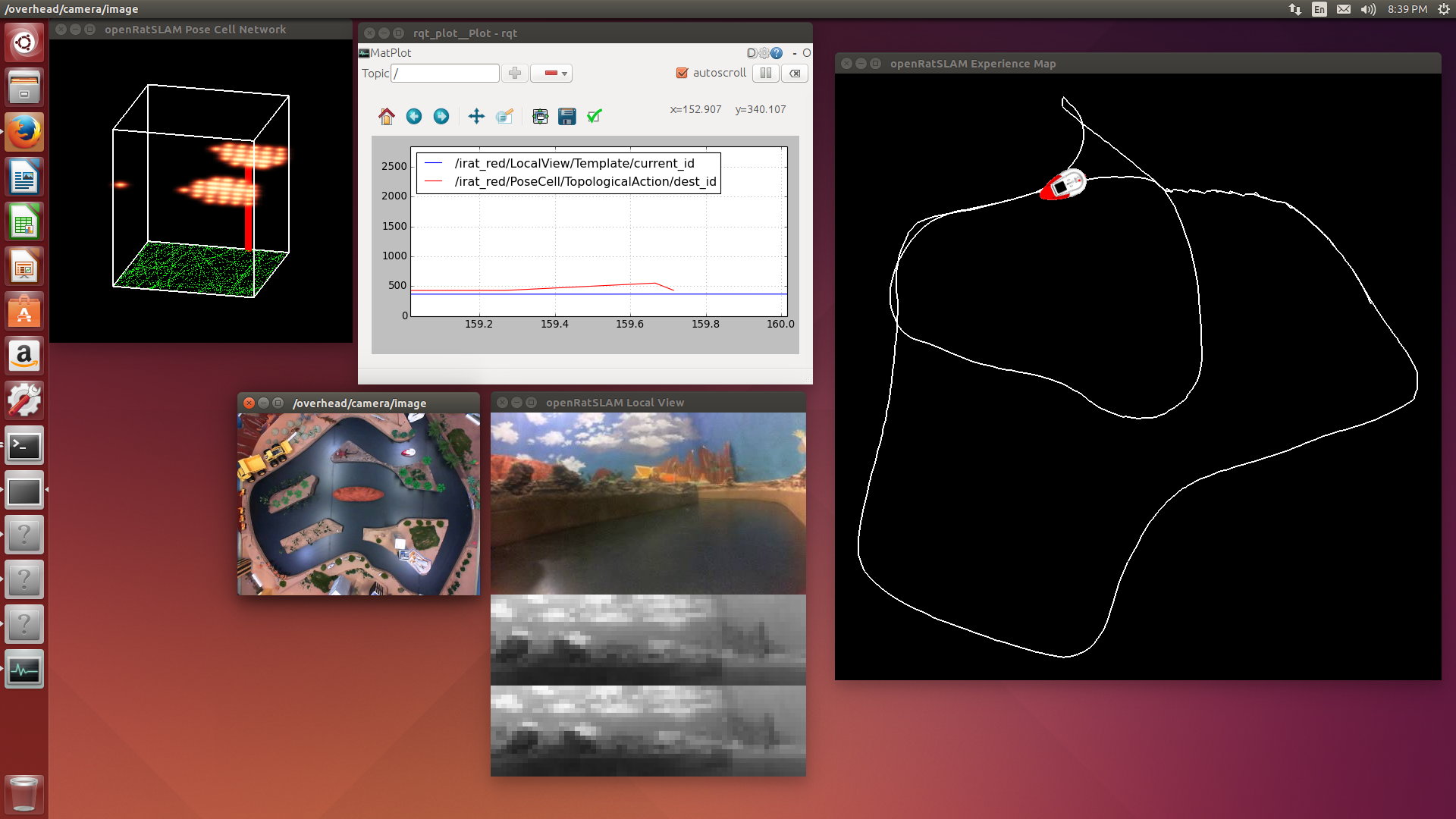

We also expanded our investigation into the RatSLAM video-based mapping software. Previously we had demonstrated that the software worked using video provided by the original author. This time we used an Android smartphone program to capture images from a phone and send them to the software. This allowed us to see how the software works when mapping The Forge HQ shop. It was clear that the software is able to get the topology of the environment, but that the poor quality of the video-based odometry made the map unreliable and unrealistic. We discussed plans to improve the odometry by using wheel encoders and an inertial measurement unit (IMU) in the drive base. Next step for RatSLAM is to see if we can tune some of its parameters to understand it better and improve the performance.